Sorry I've been MIA to answer, but my efficiency is at 82-83% when I sparge over an hour for a 12 gallon batch.

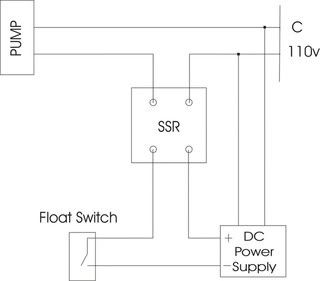

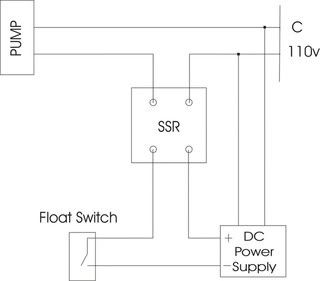

That is the correct float switch diagram to follow. But I was having a few issues with that style float system and sparging. I didn't like that the float controlled the pump between the HLT and MT. With all the on-off-on-off... I couldn't regulate the temperature of sparge water into the MT very well. Too much heat was being lost in the lines when the pump was off, followed by a spike in high temperature water once the pump was on.

I changed my system to do this. I inverted the float in the MT. I changed the wiring to activate the other pump, between the MT and BK. Now I just turn on the pump between the HLT and MT at a very slow, but CONSTANT SPARGE RATE. When the liquid level raises the float, the switch turns on the "Drain pump to the BK". This way I can throw in my temperature probe into the very top of my MT and let the LOVE controllers control the temperature of the HLT to 170 degrees. Pretty sweet setup. I don't know if anyone else is doing this, but I'll post some pictures of it. It's nice!

Here is the sparge ring with inverted switch now:

Below - "Drain turns On Position": The float rises with the liquid level in the MT and once it reaches the top, it turns on the drain

Below - "drain in the off position"

another pic. this is the back side of my heat shield. It also allows for quick attachment or removal of the plate chiller which I LOVE! The chiller just slides perfectly in the groove.