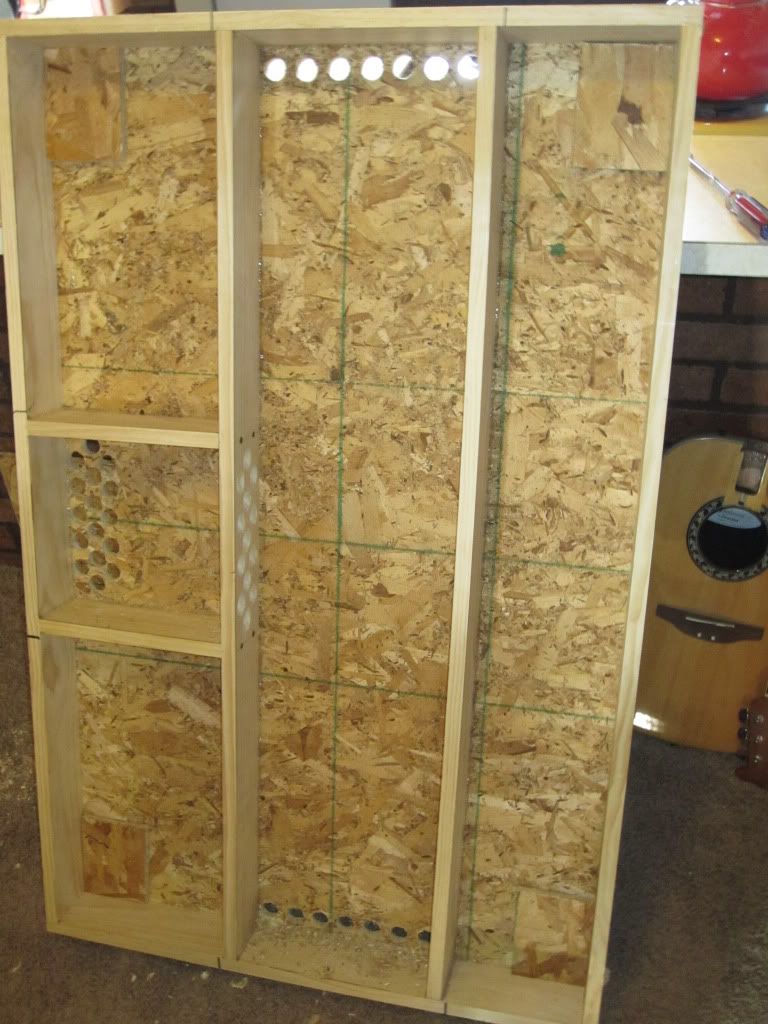

http://m1331.photobucket.com/albumview/ ... g.html?o=0http://m1331.photobucket.com/albumview/ ... g.html?o=1http://m1331.photobucket.com/albumview/ ... g.html?o=2http://m1331.photobucket.com/albumview/ ... g.html?o=3http://m1331.photobucket.com/albumview/ ... g.html?o=0ve been building a Military foot locker Jockey box, for nhc, from scratch. What I did to do this is I built two boxes. The inner box I built with 1/8" plywood which I used fiberglass to seal the inner box. Then I built the outer box large enough to allow for an air gap of an inch or two. Then I layed some styrofoam insulation on the bottom of the big box. Then placed the order box on top. Then i used expanding foam for the air gap between the boxes. This is where I made some mistakes:

1. Make sure you have enough expanding foam to fill in the entire air gap

2. Put some wood spacers between the two boxes to maintain the same gap on all sides.

3. Cut some thicker plywood that is taller than the box and the same length then place something to press against the inside of the box to help keep its shape. Also place something on top of the plywood to keep it down.

After that cut off the excess foam and cut some of that 1/8" plywood to cover the gap. Mail one end to the outside box with finishing nails. Then fiberglass from the top piece to the inner box. For a drain I used 1 1/2" pvc. I fiberglassed it to the inner box and used a test plug as the plug. Be very careful to not get fiberglass on the part where the plug is going to touch because it won't seal. I ended up redoing it using some water weld instead of the fiberglass.

I am trying out using Pex instead of stainless steel do to being cheaper we will see how well it chills the beer, I am testing it this weekend. While Pex is cheaper it is also a pain in the but to work with. I had to drill a hole at the bottom of a fermenting bucket I used duct tape to secure it on two sides and coiled the Pex along the inside of the bucket, it's easier with 2 people.

BN Army // 13th Mountain Division

BN Army // 13th Mountain Division