spiderwrangler wrote:drummstikk wrote:My girlfriend worked harder than anyone else yesterday, harvesting a huge amount of plants while the rest of us generally drank beer and posed for photos:

Yes, Asians come in handy when there's grain to be harvested...

My girlfriend is Asian???

Ah...yep, I see it now.

Never really clicked until you posted that highly illuminating and on-topic photo.

iceclimber wrote:Awesome job, and great dedication...I enjoyed reading about your progress and all of the issues you had with growing your own grain

Thanks for your kind words! I think I may have overplayed the difficulties, mostly because I was interested in them. But I don't want to discourage people from trying this out if they have some land. If you throw some grains in the ground and irrigate them (or not even if you live in the East or South), you're going to get barley.

iceclimber wrote:the photos were great too...

I know, right? The pics were by Jesse Friedman from Almanac. He's an awesome photographer.

iceclimber wrote:let us know how many pounds you acquired

Coming up! And, see below...

Oy, what a week! After an evening of harvesting on Monday and bundling, raking, and fertilizing on Tuesday, the field was roto-tilled by Webb Ranch on Wednesday morning, and then I hoed out rows for the corn people:

and with that, my work is done!

Just for comparison, here's what the field looked like last November:

I think I dug better rows back then.

Well, the timing was last-minute, just like I wanted it to be. The corn kids came in today setting up netting to protect their seeds and seedlings:

While the Conlon is drying, I got all the Scottish bere down to seeds. I cut heads off of plants last week:

In retrospect, it was not the best to put these heads on the ground. The awns are super-catchy, and they pick up sticks and rocks, which remain with the grains, even through winnowing.

It was enough heads to fill up a 100 gallon garbage pail,

and enough straw to fill up a giant wheelbarrow full of hay!

Solo hayride, anyone?

The thresher really had some problems removing the awns from this variety -- it could be the fault of the thresher (fixed concave) or the landrace bere. Anyway, it wasn't working. So I put on my calf-high boots and climbed in the garbage pail! After stomping around while I watched an episode of Modern Family, the chaff was reduced to a free-flowing consistency. I poured the slurry in front of a box fan several times, and I ended up with 8.2 lbs of grain!

8.2 lbs in 4 x 33' rows, spaced at 14" is 2300 lb/acre.

Commercial bere yields are 2500-3400 lbs/acre. I'm not too far from the low end of commercial yield -- all right!

You might already guess that the commercial yield for bere is a lot lower than the yields for modern 2-row barleys; they are closer to 4-7k lbs / acre. Now check out the difference in the grains:

The bere (right) is much longer and thinner than Conlon (left). (Conlon is an especially plump modern 2-row, and bere is a pre-industrial 6-row, so this is an extreme comparison.) This makes the ratio of protein to starch a lot higher in bere. My guess is that most barley used to be more like the bere, with skinnier grains. Academic and industrial breeding selected for more starchy grains, but bere never caught that train. Today, maltsters and brewers would never choose to include excess nitrogen in their products -- excess soluble protein can lead to hazing, and excess free amino nitrogen can lead to shorter shelf life and the proliferation of contaminating microbes. Still, I think it's pretty cool to at least have access to the old stuff. After all, the

English word for barley used to match the

Scotts word bere -- an etymological reminder that bere is a window into beer's past. Sadly, 8 lbs isn't enough to make a bere beer and have any left over for a future crop. This all must be used for seed. But next year...next year.

The Conlon is drying out nicely. Kernels from the slowest portion of the field still yield a bit to a fingernail, so they're not ready to thresh. But my girlfriend wants to get threshing, so I think we'll try some primary tillers from the most advanced bundles this weekend:

On to hops!

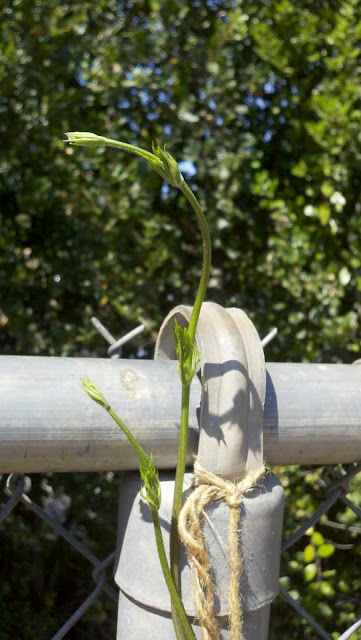

More burrs from the precocious columbus bine. I think I misjudged the new nodes in a previous post, because these are definitely the precursors to cones:

I realized I have really been slacking on the hops farming. To be fair, there wasn't much to do. But now that the barley is done, and the hops have a little bit of growth, I have been trying to learn more about how to prune them. It seems the consensus is to have two twines per crown, 3 bines per twine. That's a total of six bines per plant -- everything else gets pruned. All my plants are either transplanted 2nd years or transplanted crowns from Great Lakes Hops, so I'm not going to do the 1st year rhizome technique of letting every single bine grow.

That's the idea at least. Let's just say that in practice, mistakes were made.

First mistake: if you see three bines crawling up a twine, don't assume they all have living tips! Sometimes the tips have died (due to transplanting damage in this case), and then if you prune away all the other basal bines, you're left with fewer than the desired six bines per plant. Oops. This mistake isn't so bad, because more basal shoots can grow, and the bine I mistakenly pruned wasn't very far along.

Second mistake: Don't forget to check if the bine you're pruning is an early lateral to a trained bine. I have no idea why my Cluster plant had such an early lateral. But I decided it needed to go, and didn't realize that it was connected to a strong main shoot. I followed the bine down to the ground and cut, instead of clipping the lateral off at the axil like I should have. Of course, I cut the trained bine off, which was already 3-4 feet up the twine. Will be painful watching it turn brown and crispy. This is a terrible mistake to make, because it destroys a lot of good growth. At least nobody likes Cluster.

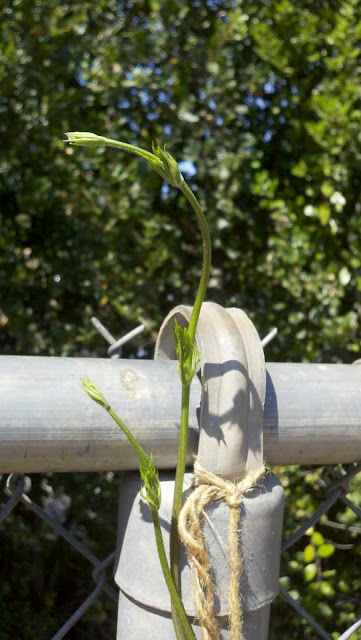

Ok, enough with the hand-wringing. There is an interesting choice to make when growing with a low trellis. I have a 6' fence. I can either allow my bines to grow horizontally along the fence, or I can encourage them to grow laterally by clipping off apical tips when the bines reach the top.

Most of us would probably think to let the bines grow horizontally, because this is what we've been told to do, mostly because commercial hop yards are set up for 16' or 18' trellises. Well, it turns out you can get

decent yields from common hop varietals with a low trellis. The technique involves planting rhizomes just 2-3 feet apart and cutting the apical meristem rather than training it to grow horizontally. Still, the low trellis system never beats a traditional 18' trellis unless you're growing a dwarf hop.

But what about the bushy low-trellis training vs. horizontal low-trellis training?

Does anybody know if this low and bushy technique actually produces a better yield than the horizontal growing technique?I want ahead and tried it on two bines. I don't know if I'll have a great comparison since I don't have any duplicate crowns, but there you have it -- an uncontrolled experiment:

I also see brown tips and fringes on some of the older leaves:

Anybody know what's going on here?

Anybody know what's going on here? I am watering at 1/3 gallon per plant 3 days a week. I upped it to 1/2 gallon just in case this is water stress.