Today was brewday! Luckily, there were two skilled brewers on hand from Hermitage / Tied House Brewery to take care of this 25 barrel mash tun:

and boil kettle:

We mashed in, and I was sure I could see my little caramel grains in there somewhere:

Maybe those small dark dots?

Hmm, maybe not.

But there they are!

Because the grains were still not bone dry when they went through the mill, most of them were not broken into pieces, but still broken open:

Some were not broken at all:

This could just be due to the mill, but I bet these grains would be below the plump cutoff if I had run them over a screen.

This was fun!

and the brewers were more than happy to let an enthusiastic home brewer rake out the mash tun. Anything is fun the first time, right?

Jesse Friedman from Almanac showed up with 80 lbs. of Cascade, Chinook, Ivanhoe, and Gargoyle (Gargoyle???) that were picked THIS MORNING in Lake County.

The Ivanhoe is a modern-day mimic of Cluster, and has a subdued aroma as you'd expect with American-type resiny and hop oil aromas. The Gargoyle on the other hand had a fruity grape-like aroma. It was really fantastic!

They promptly found their way, tags and all, into the mash tun, which was to be used as a hopback:

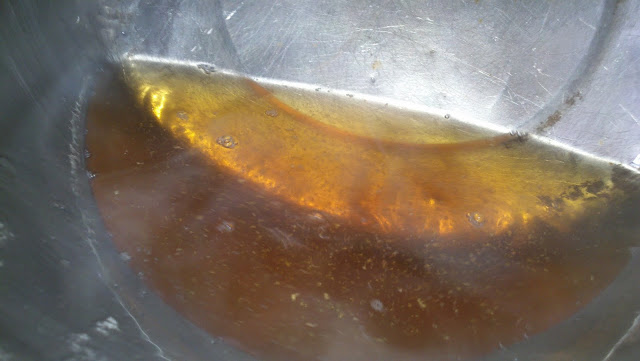

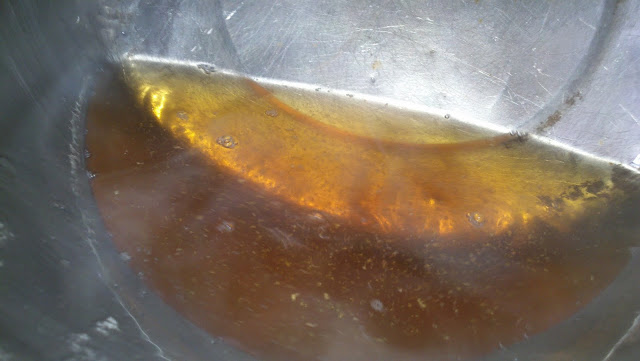

Meanwhile, in the boil kettle, this happened:

a scaled-up version of the meringue-like stuff you see right before your kettle boils, which lead to this:

I realize it's a bit tough to asses the color without a clear glass and some sense of scale, but let me tell you -- it was darker and more golden orange than you would expect from base malts alone. Even at 4-5% of the grist, I see the field in there!

From this point on, it's in the very capable hands of Peter and Greg, two brewers with Hermitage. Can't wait to taste it!

Now, on to that other goal: 100% homegrown