Soft or rigid liquid lines?

Posted: Thu Mar 25, 2010 9:34 am

by Husker267

I'm designing a 2 tier brew stand after Push's and trying to come up with a liquid flow design. I came across an Australian homebrewer that used rigid liquid lines, but used compression fittings at the junctions for dis-assembly. It looked awesome as compared to the high temp flexible plastic, but I wonder how much a pain in the ass it is to clean following a brew session? Unfortunately I can't find the link to his build.

My thought is to possibly run hot PBW through the lines after a session to clean them out. Any feedback is appreciated

Re: Soft or rigid liquid lines?

Posted: Thu Mar 25, 2010 9:57 am

by Grist Licker

I use silicone tubing and I pump hot PBW through them for cleaning. I don't see why you couldn't do the same with a rigid hose. Make sure you don't use water over 180F and be sure to rinse really really well.

Re: Soft or rigid liquid lines?

Posted: Thu Mar 25, 2010 10:00 am

by Husker267

Thanks for the feedback Grist. Just to clarify, the lines this gentleman ran appeared to be stainless. So boiling wort shouldn't be an issue. I was looking along the same lines or possibly copper.

Re: Soft or rigid liquid lines?

Posted: Thu Mar 25, 2010 10:28 am

by Kbar

Copper is easier to work with. Major breweries have many feet of stainless tubing and use similar CIP techniques. Do what Grist said, PBW loop at <180F and clean water rinse, with acid final rinse on the at risk areas for cold side wort (i.e. post CFC or chiller). I use teflon core stainless outer braid for most of mine on the BK and then high temp silicone on the MLT/HLT. I do use some rigid stainless tubing, but flare for JIC, use a mandrel bender and use the appropriate JIC/pipe based stainless fittings.

Copper is a great DIY option for rigid tubing, I just have a fetish for all things stainless

Re: Soft or rigid liquid lines?

Posted: Thu Mar 25, 2010 6:46 pm

by Grist Licker

Kbar wrote:acid final rinse on the at risk areas for cold side wort

What do you use for an acid rinse?

Re: Soft or rigid liquid lines?

Posted: Thu Mar 25, 2010 6:58 pm

by Kbar

Sorry, should have been more detailed. This is a clip from 5-Star. I use Star-San (across the board final rinse and sanitizer) and Saniclean for CIP. Will try to paste in their description. I run a Saniclean loop at 160F prior to boiling the wort as I need to clean the CFC and tubing for transfer to the conical. Star San for all else, including a large tub for soaking all parts as I go through the brew day, and conical parts as well. 5-Star is a life saver for us homebrewers.

Star San

is an Acid Anionic Sanitizer, accepted by the U.S.D.A as a General Sanitizer in all Departments.

Star San is a synergistic blend providing a unique killing system, unaffected by organic soils and

delivering a self-foaming formulation for optimum coverage and penetration. Formulated to impart no

off-odors or flavors, Star San is a No-Rinse sanitizer when used at 200 ppm. Unlike other sanitizers,

Star San is non-staining on your equipment and hands, non-corrosive on stainless, and stable over a

wide temperature range.

Saniclean

is an Acid Anionic Final Rinse. Saniclean is formulated to be low-foaming at temperatures over 70" f

and is also unaffected by organic soils. Formulated to impart no off-odors or flavors, Saniclean is a

No-Rinse product when used as directed. Saniclean is also non-staining on your equipment and hands,

non-corrosive on stainless, and stable over a wide temperature range. When allowed to air-dry,

Saniclean leaves your brewing equipment in an acid condition, inhibiting contamination between uses.

Re: Soft or rigid liquid lines?

Posted: Tue Mar 30, 2010 5:11 pm

by 11amas

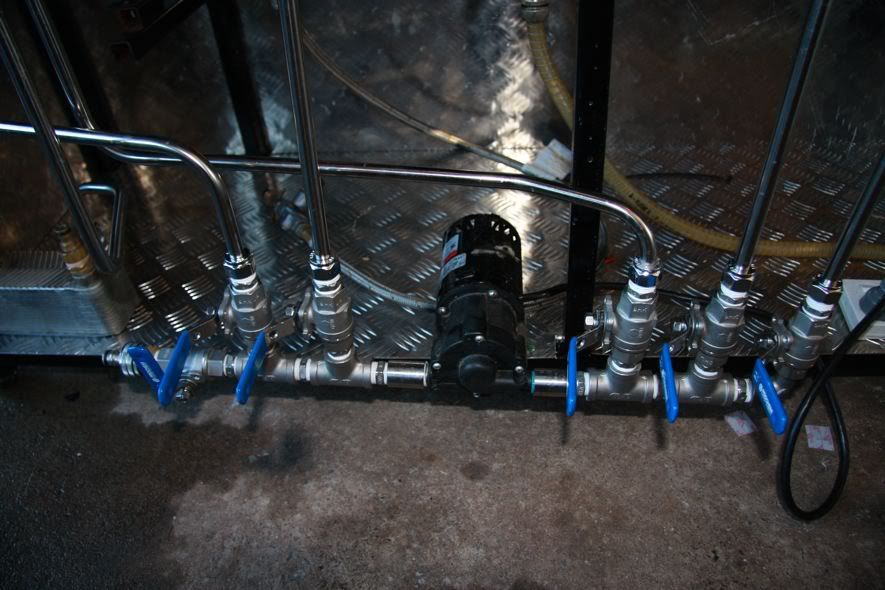

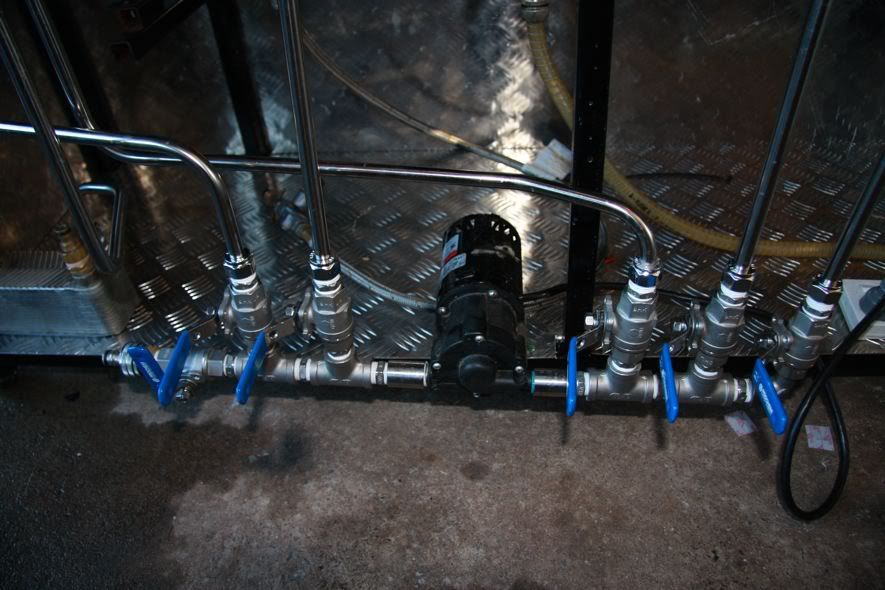

+1 on the CIP idea. I saw a really nice setup with dual pumps, SS lines, compression fittings, etc. The guy doesn't take things apart, just uses hot PBW recirculated, followed by a water rinse, and then an acid recirc.

Re: Soft or rigid liquid lines?

Posted: Wed Mar 31, 2010 3:06 pm

by rustyc30

I have recently upgraded to all Stainless lines and loving it. As for cleaning everything gets flushed with water after a brew then hot PBW let it sit for a little then flushed again then just run starsan through the lines and it's all done.